A Primer on ATV CV Joints: How it is Integral to Your Machine

ATVCamper 03.21.12

Utility ATVs have come a long way, especially the ones with 4-wheel drive and independent suspensions. Four wheel independent suspension offers improved rider comfort and handling. But the independent suspension or 4-wheel drive would not be possible without the Constant Velocity Joint or CV Joint.

The ATV CV joint is part of each individual drive axle and is a very durable part of the ATV if it is kept clean and inspected regularly. On an ATV independent suspension there are four axles, one for each wheel, and each of these axles will have two CV joints which allow the wheel to articulate with the suspension while receiving constant power through the varying angles of the axle.

The ATV CV joint is part of each individual drive axle and is a very durable part of the ATV if it is kept clean and inspected regularly. On an ATV independent suspension there are four axles, one for each wheel, and each of these axles will have two CV joints which allow the wheel to articulate with the suspension while receiving constant power through the varying angles of the axle.

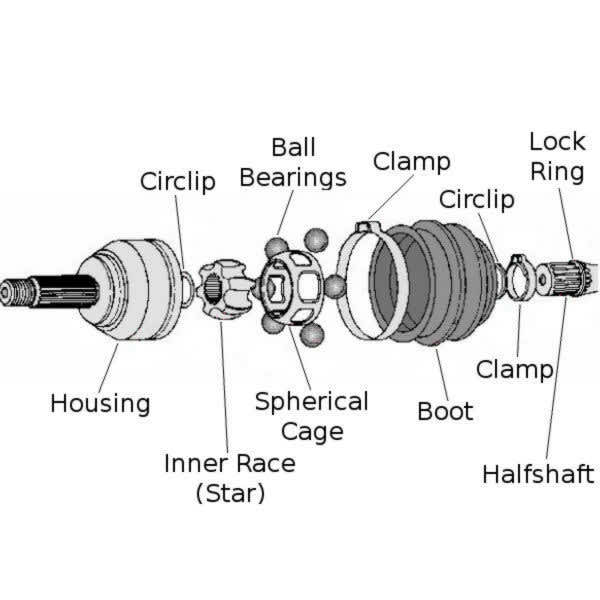

Most ATVs use the Rzeppa or ball and groove type of CV joint which consist of a cup-shaped outer housing, a spherical center race (star), six steel ball bearings and a spherical cage assembly. The outer housing has six grooves machined into it that line up with the six grooves of the spherical star. These six grooves hold the six ball bearings. The balls are held in position by windows or slots cut into the cage assembly.

The CV joint is designed so that when it bends with wheel movements, the axle is still able to transmit engine power to the wheel at a constant velocity without addition friction or play. Since the front wheels turn as well as move up and down with the suspension, the CV joints on the front axles are exercised in every direction and at angles up to 50°.

The ATV CV joint preforms amazingly well but they are most vulnerable at extreme angles at full power. The joint is protected from contaminates by a rubber boot and this boot must be kept clean and inspected regularly for cracks and holes. Damage to the boot can come from normal wear to branches and other trail debris.

The ATV CV joint preforms amazingly well but they are most vulnerable at extreme angles at full power. The joint is protected from contaminates by a rubber boot and this boot must be kept clean and inspected regularly for cracks and holes. Damage to the boot can come from normal wear to branches and other trail debris.

If any damage to the boot is found it must be replace immediately, otherwise damage to the CV Joint will result requiring an expensive repair or replacement. Replacement of a damaged CV boot requires removal of the axle and is not an easy task the first time. Follow the ATV manufactures boot replacement procedure or have a reputable mechanic preform the repair. It does get easier each time you replace a boot.

If a CV joint gets damaged it will start making noise, a clicking or grinding sound. If the joint has failed altogether then it will no longer transmit power to the wheel. ATV CV Joints are a critical component of the ATV inspect them often. Get out and ride!