DIY – Wind-On Leader Serving Bobbin

Eugene L. 04.30.24

Sometimes you just need to make your own rigging tools when time is short. I had a fishing trip coming up in a couple days but had lost my PR Knot Bobbin that I used to rig up my wind-on leaders. So instead of being out of luck, I decided to make my own Wind-On Leader Serving Bobbin using some PVC fittings and other parts I got at the local hardware store. To make this DIY Wind-On Leader Serving Bobbin you will only need one power tool, a cordless drill, and some drill bits.

DIY Articles on OutdoorHub

- DIY Custom Gun Case Foam Replacements

- DIY Camo Painting a Rifle Stock with Sea Sponges

- DIY Rod Holders for Collapsible Pier Cart

- DIY Ghost Shrimp Pump – Catching Your Own Bait

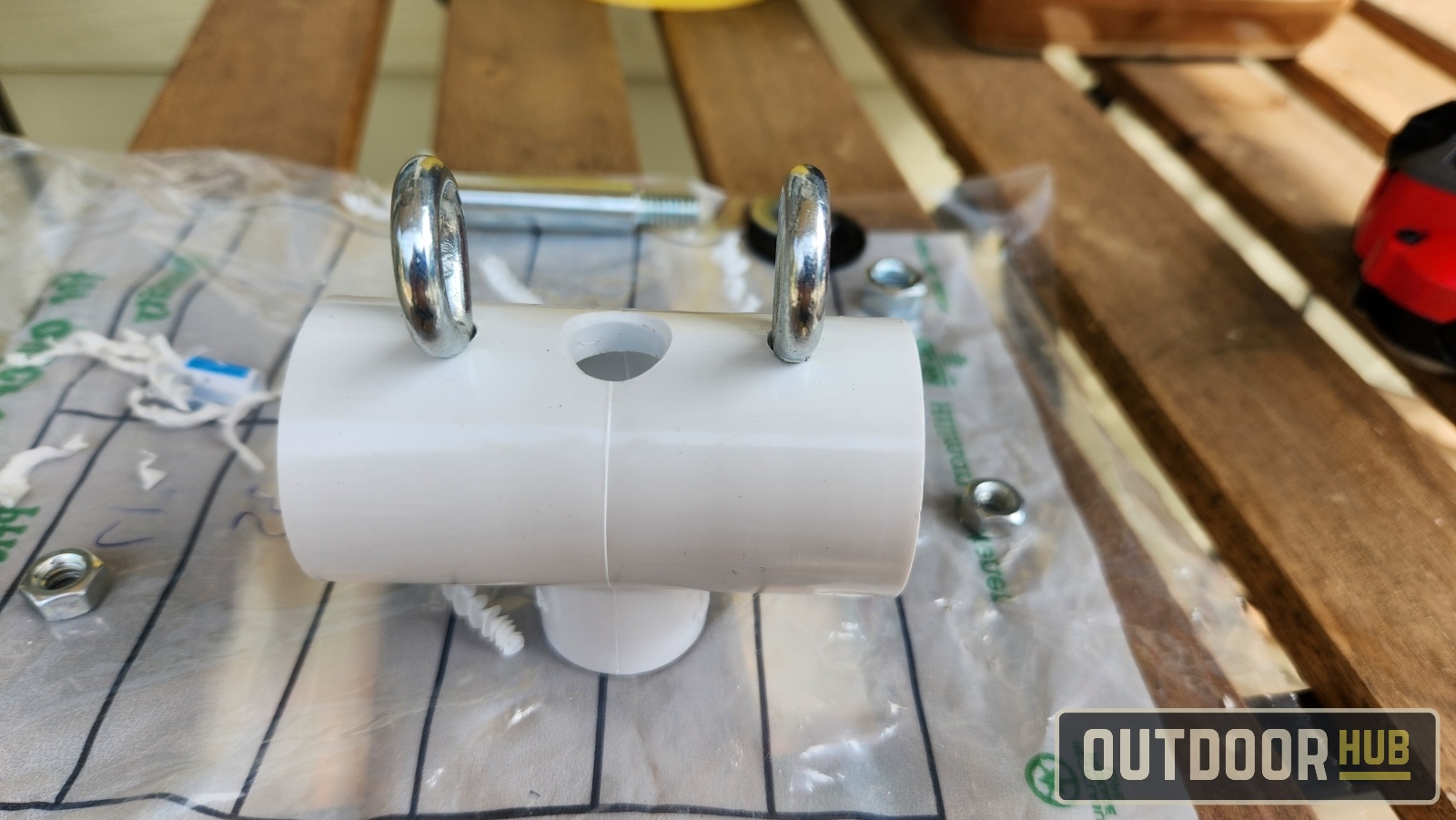

To make this, I bought 1- 1″to 1/4″ reducing T, 2 – threaded eye bolts, 1 – axle bolt and nut, 1 – washer, 1 – rubber washer, and, 2 rubber o-rings. You can probably just use a 1/4″ T PVC fitting instead of a reducing one but I used on that the eye bolts and axle bolt it on. If your hardware store has other bolt options go for the smaller PVC fitting.

The first step is to drill a small pilot hole in the middle of the “T” PVC fitting. You want to gradually work your way up with drill bits in size so the PVC doesn’t grab the drill bit and hurt you. But if you have a vice or drill press, you can skip this step if you can lock down the T piece. If you do have those tools you can just start with the largest drill bit with no worries. After you finish drilling make sure to deburr the hole.

The next step is to drill the holes for the two eye bolts into the PVC pipe fitting. I just set up eye bolts on the axle bolt as it would be for it’s final configuration to figure out where to drill on the PVC pipe. Then I just drilled two small holes just big enough for the eye bolts.

Take apart the eye bolt – axle bolt set up and place the eye bolts into the holes you drilled. Use the provided nuts and lock the eye bolts into place.

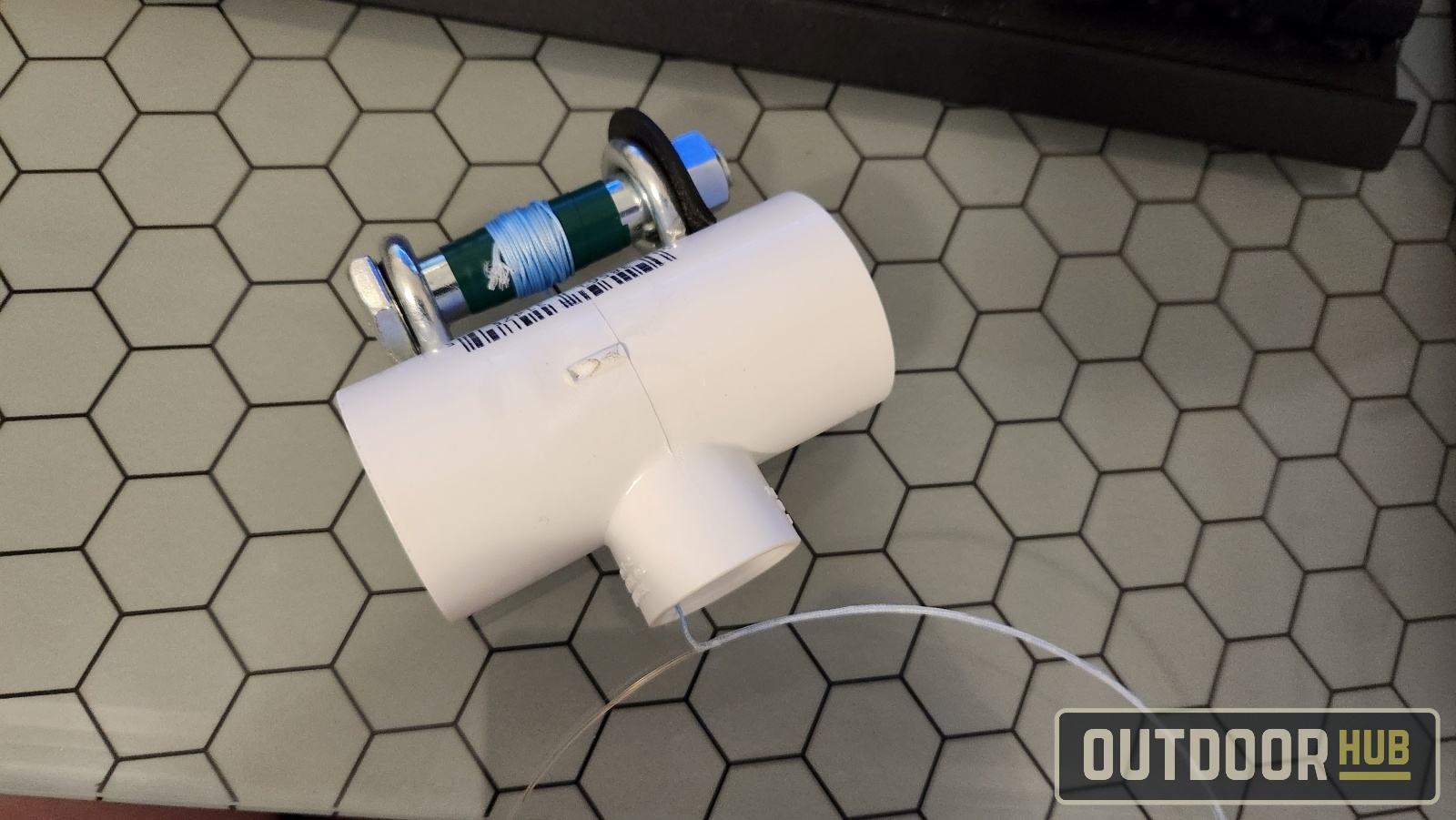

Next grab the eye bolt and put one of the o-rings onto it, sliding the o-ring all the way up to the head of the axle bolt.

Then slide the axle bolt into the eye-bolts on the PVC fitting. Then put the rubber washer and metal washer on the bolt. Top them off by threading on the nut behind the washers. The washer and o-ring act as a source of friction for you to adjust the tension on this wind-on leader serving bobbin.

Next, you want to notch the 1/4″ side of the PVC fitting, I used a heated nail and a small drill bit to make the notch. Then a sanding pad to round off any sharp or hard edges, you want to make sure anything that could possibly damage your line is taken care of. The purpose of the notch is to cradle your leader as you finish serving any leaders you are trying, that way the bobbin stays in place more easily.

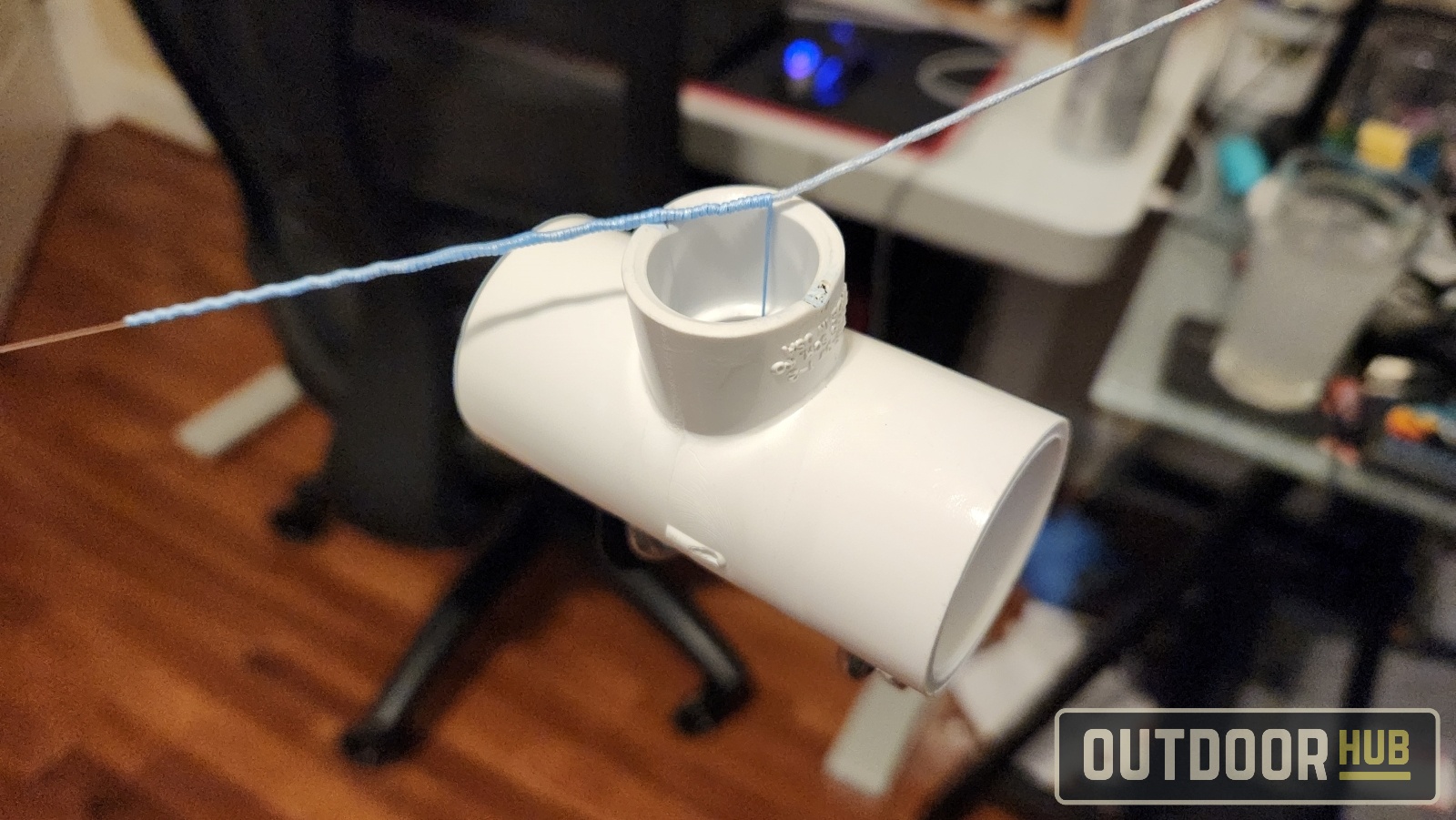

The final step to finish off the bobbin is to throw a bit of electrical tape onto the axle bolt. That way your braided mainline doesn’t slip when you are putting tension as you are serving a leader.

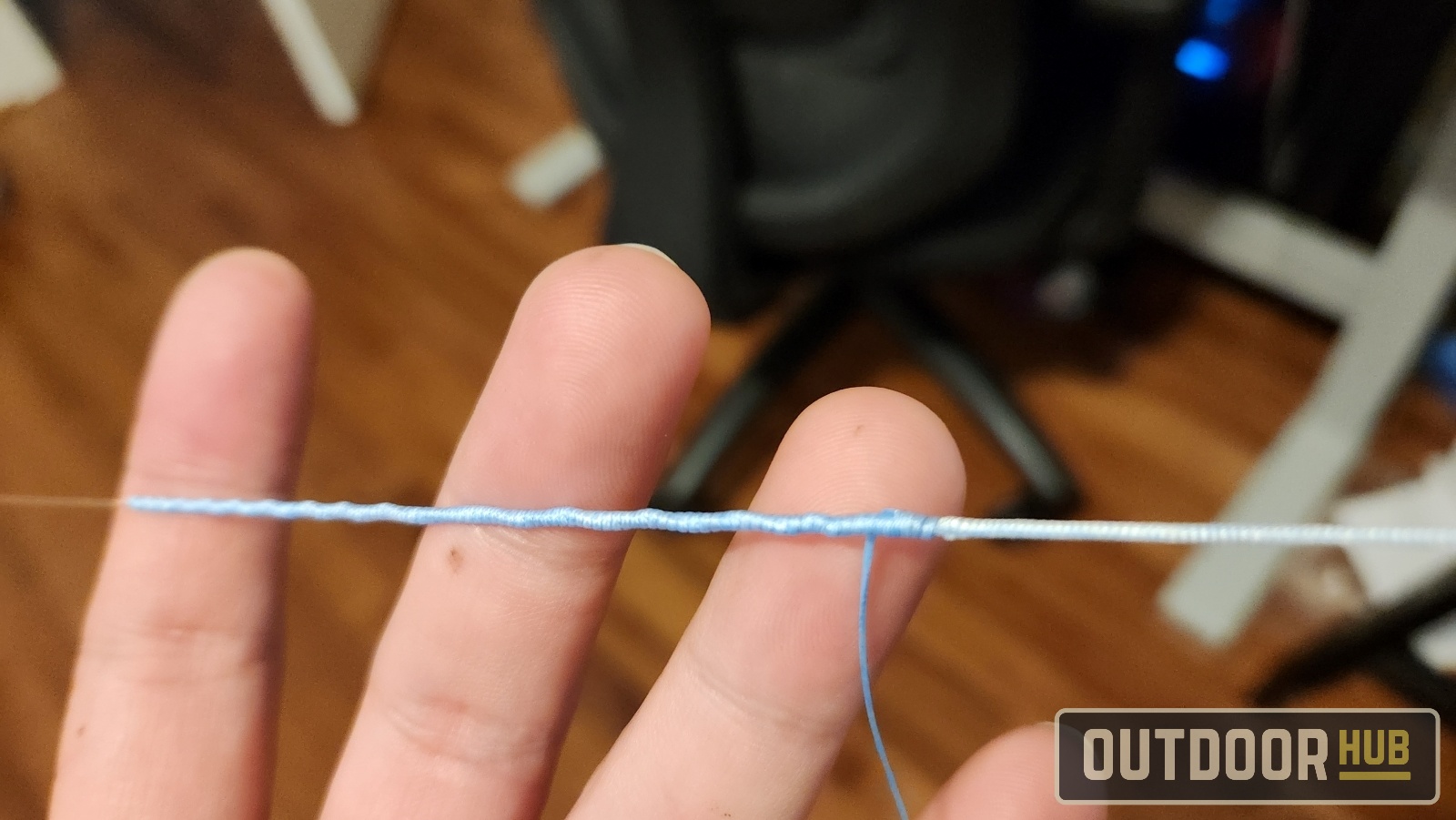

Here I am using my DIY Wind-On leader serving bobbin to tie up a serving knot to finish the connection between my 80lb hollow-core braid and a 60lb monofilament top shot on one of my trolling rods. By using the tension provided by the rubber washer I am able to make two layers of tight wraps of line around the leader to lock the line into place. After which a reverse Uni knot locks the loops down making for a 100% knot strength connection that can easily run through the guides of any rod. So if you have a trip coming up in the next few days and don’t have the time to order a bobbin, consider making your own. This takes a minimal amount of effort and cost me less than $15 to make and took less than an hour to assemble. It doesn’t work as well as a purpose-made commercial Wind-On Leader Serving Bobbin but it does definitely work in a pinch making serving knots.